Navigating the Chinese Market: Selecting Premier Casting & Forging Suppliers

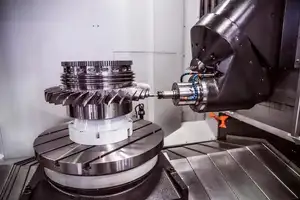

Casting and forging are essential processes in the manufacturing of a wide range of products, from automotive components to industrial machinery. China, with its robust manufacturing sector, has become a key player in the global casting and forging market. This guide is designed to assist global purchasers in selecting reliable and high-quality casting and forging suppliers from China.

China's Casting & Forging Export Landscape: An In-Depth Analysis

China's casting and forging industry has been on an upward trajectory, with exports expanding due to technological advancements and a commitment to quality. The Chinese government's supportive policies and significant investments in R&D have played a pivotal role in this expansion. The current export landscape is characterized by a diverse range of products, from precision castings to large forged components. Chinese casting and forging products are recognized for their precision, reliability, and cost-effectiveness, making them a popular choice among global buyers.

Classification and Advantages of Chinese Casting & Forging Products

Chinese casting and forging products can be categorized into several types, each with its own set of advantages:

- Precision Castings: Known for their close tolerances and intricate designs, these castings are ideal for components requiring minimal post-processing.

- Sand Castings: Suitable for a wide range of materials and designs, sand castings offer versatility and are cost-effective for prototyping and low to medium production volumes.

- Forged Components: Forged from metals, these components are strong and durable, often used in high-stress applications such as automotive and aerospace industries.

- Die Castings: Offered in both aluminum and zinc alloys, die castings are characterized by their high production efficiency and precision.

- Investment Castings: Also known as lost wax castings, these provide exceptional surface finish and are used for complex geometries.

Strategies for Global Buyers: Sourcing Casting & Forging Products from China

When sourcing casting and forging products from China, global buyers should consider the following strategies:

- Market Research: Investigate suppliers' market reputations, product quality, certifications, and customer reviews.

- Request for Quotation (RFQ): Send RFQs to multiple suppliers to compare prices, product specifications, and delivery terms.

- Quality Assurance: Arrange for third-party inspections to ensure the products meet your quality standards.

- Relationship Building: Establish long-term relationships with reliable suppliers for better service and potential cost savings.

- Regulatory Compliance: Be aware of import/export regulations in your country and China to avoid legal issues or additional costs.

Top 5 Chinese Casting & Forging Suppliers: A Closer Look

Here's an overview of five leading Chinese casting and forging suppliers, their product advantages, and the categories they offer:

| Supplier Name | Product Advantages | Product Categories |

|---|---|---|

| Maanshan Great Wall Machinery Co., Ltd. | Specializes in large-scale forgings with a focus on quality and precision for heavy machinery applications. | Axle Forgings, Crankshaft Forgings, Gear Forgings |

| Shanghai Jinjiang Casting & Forging Co., Ltd. | Offers a range of precision castings with tight tolerances and excellent surface finish. | Precision Castings, Aluminum Die Castings, Zinc Die Castings |

| Dalian Dongfang Precision Casting Co., Ltd. | Known for its investment castings used in aerospace and high-performance automotive components. | Lost Wax Investment Castings, Stainless Steel Castings, Alloy Steel Castings |

| Hebei Xinhe Forging Co., Ltd. | Provides a comprehensive line of open-die forgings with a focus on durability and strength. | Open Die Forgings, Closed Die Forgings, Ring Forgings |

| Anhui Jianghua Forged Co., Ltd. | Recognized for its high-quality rolled ring forgings used in various industries for critical applications. | Rolled Ring Forgings, Disk Forgings, Module Forgings |

These suppliers represent a cross-section of the Chinese casting and forging market, offering a variety of products that cater to different manufacturing needs. When selecting a supplier, consider their product specifications, reputation, and how well their offerings align with your specific business requirements.

By employing these strategies and leveraging the insights provided, global buyers can confidently navigate the Chinese market and secure high-quality casting and forging products that will enhance their production capabilities and competitiveness in the global manufacturing industry.